Screen Printed Decals

Screen Printed Spot Color Decals, Pantone PMS Decals and Labels

Custom printed decals are and always will be one of the best marketing tools for promotions and as advertising hand-outs. The minute a consumer sticks them on something, they start advertising for you. We'll look at the advantages of having those decals screen printed. The first benefit is that we can match very specific colors through the Pantone® color matching system. Screen printed decals are also called spot-color decals for this reason. The result is truer, more vibrant colors. They are some of the highest quality decals we make. Because so much ink is deposited, they are incredibly durable. That means they're weather-proof and fade-resistent. In addition, decals can also be screen printed on a variety of substrates including vinyl and polyester. This is especially important given the number of decals and labels we screen print for use on industrial machinery.

VINYL DECALS

Just like ink colors and design, the material used for your decals should also be considered. When choosing a substrate, there's a lot more to think about than just the finished look. For example, pressure-sensitive vinyl like 4 mil white or 4 mil clear are the most common choices for screen printed decals. Since it's more economical to use than polyester, vinyl is better suited for general purpose decals. Additionally, they are more pliable than Mylar® polyester. This means they will conform to irregular surfaces like a motorcycle helmet or car bumper.

CUSTOM PRINTED VINYL DECALS FOR ADVERTISING PROMOTIONS

Because they're so malleable, vinyl decals are perfect for promotions where they're likely to be stuck to "gear;" whether that's snowboarding, motorcycle, bicycle, or any sports equipment. The Current Coasters® decals below are a great example of vinyl decals as a promotional give-away. With their bright colors and interesting design, coaster-enthusiasts are sure to stick these to their gear. And when they do, they'll be sharing Current's branding with their friends. Can't ask for better marketing than that.

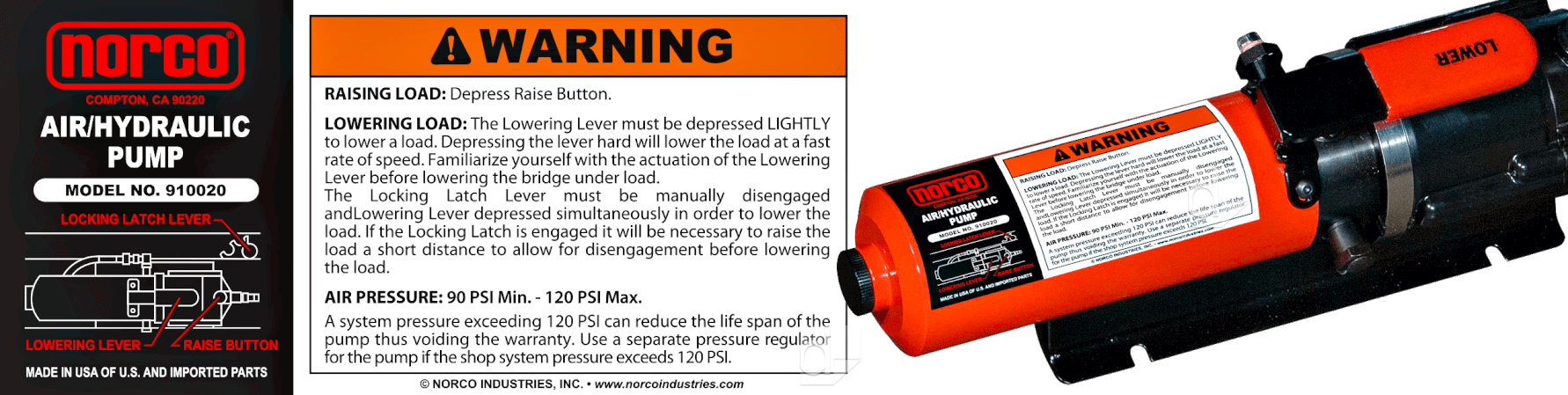

VINYL DECALS FOR EQUIPMENT MACHINERY

Although we make a lot of decals for marketing purposes, screen printed decals are also great for use on industrial equipment and machinery. Because of their durability, we also print a lot of spot-color decals for equipment-use directions like these for Norco®. These are two from a set of 14 decals we made for them. They were all screen printed on 4 mil white vinyl (some 2 spot colors; some with 3). They were also square cut and included a crack-and-peel slit liner on the back.

MYLAR POLYESTER DECALS

Mylar is a brand name of polyester substrate. So, why use Mylar for decals? The short answer is that they're just cool. With shiny chrome mirrored or brushed silver metallic finishes, nothing else looks or preforms like a Mylar decal. The caveat? They'll cost you. Mylar decals run about 2-4 times the price of a standard vinyl decal. Mylar is also used for specific purposes; for instance, decals that need to withstand up to 275° temperatures. Additionally, they are thinner than vinyl decals at just 1-2 mil in thickness. This produces a lower profile, giving a more "finished" look than their vinyl counterparts. Lastly, it's important to note that Mylar decals are not very flexible. While they're great for flat surfaces or a single-curved surface (like a metal tube on a bicycle frame), they won't conform to a compound surface.

DECALS PRINTED ON BRUSHED SILVER MYLAR

These 3.75" x 1.75" decals for King Suspension® were screen printed with 3 spot colors on 2 mil brushed silver Mylar and custom die cut. I can't do justice to the brushed silver finish in this rendering, so you'll just have to trust me that they make quite an impact. It's decals like these that have made King's marketing promotions so successful. (note: these decals were later domed for King Suspension).

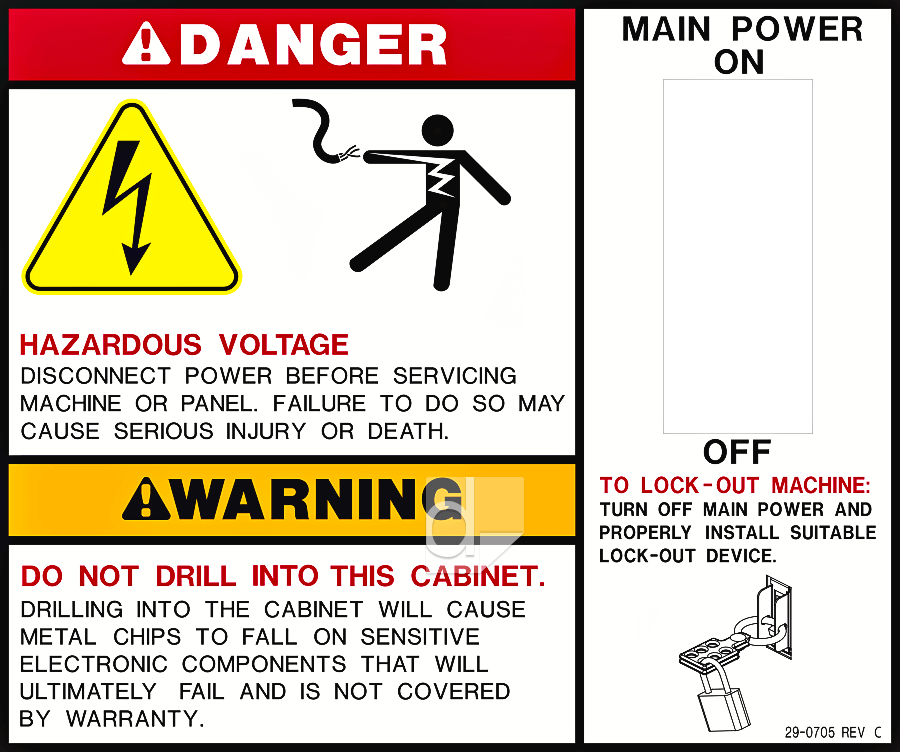

MYLAR DECALS AND LABELS FOR MACHINERY

When a decal needs to be both vibrant and hard-wearing, Mylar is the best option. That's why we screen print so many polyester decals for warning labels on industrial machinery. The sample below was printed for use on Haas® milling machines to warn of hazardous voltage dangers. They were screen printed with 4 spot colors on 2 mil white Mylar polyester with a 2 mil gloss Mylar laminate on top for added durability. They have permanent adhesive and a crack-and-peel slit liner on the back. They were also custom die cut to 8.375" x 7" with a rectangular window cut-out for the switch.

LAMINATION ON SCREEN PRINTED DECALS AND LABELS

After your decal is printed, lamination will provide added durability and enhance its finished look. We offer a wide variety of laminates; polyesters, vinyls and polycarbonate. Polyester laminates are best suited for protection against grease, oils and mild solvents. Soft vinyl laminates maintain the flexibility of a decal while protecting its ink from scratching. When polycarbonate is laminated to a vinyl or Mylar polyester decal, it performs much like a Lexan label.

The most economical solution to add a little durability with a lot of punch is a high gloss UV clear-coat that’s screen printed onto your decal. The warning label for Haas' milling machines (above) have a 2 mil gloss Mylar laminate over them and the labels for Norco have 1 mil Mylar. Both were laminated for hard-wearing performance in an industrial environment since they will go on machinery.

DIE CUTTING AND FINISHING VINYL DECALS

To finish your decal we offer custom die cutting (including holes for buttons and switches on industrial decals), sheer cutting for simple square corners and, for easy application, crack-and-peel slit liners. Your decals are then conveniently packaged in poly bags.

If you want to know more about our Screen Printed Decals, give us a ring at (714) 998-5266 or fill out our free quote form.