Double Sided Window Clings

2-Sided Vinyl Window Cling Decals and Push-Pull Door Clings

Dilco is the industry leader in custom printed double-sided window cling decals and door clings for retail store fronts. Made of vinyl or polyester, with block-out or barrier film, window clings can be seen both entering and exiting the store. If windows are the first line of sight to your branding, then it makes sense to use glass to advertise; it doubles your exposure from both inside and outside the store at the same time.

THE HUGE MARKETING ADVANTAGE OF DOUBLE-SIDED WINDOW CLING DECALS

Double-sided window clings announce your product before a customer even steps foot in the door. In marketing, getting your product noticed is everything. Brand recognition, sales promotions, calls to action, and point-of-purchase impulse-buys rely heavily on reminding consumers that they either already like your product or want to try it. By advertising that product before they even enter the store (in the case of window clings) or as they open the door (as with door clings), you're miles ahead of the game. Moreover, when custom die cutting, bright graphics, easy-to-read text, and product images are included, it not only makes shoppers want to purchase your product, some may enter the store specifically looking for your product.

HOW DOUBLE-SIDED WINDOW CLINGS ARE MADE

When window clings are double-sided there are a variety of printing methods and materials used. Whenever you see a description like 4/4-color process or 2/1-spot color, it means the decal is double-sided or double-faced. For example, 4/4 means the decal was 4-color process printed on each side. Likewise, 2/1 means the decal was screen printed with two spot colors on the front and one spot color on the back.

PRINTING METHODS

Window clings can be either UV offset printed, screen printed, or digitally printed. The type of graphics and size of the run determine the printing method. For instance large quantities of window clings with spot-color graphics are screen printed. Small quantities requiring photo-quality images are more cost-effective to 4-color process digitally print.

SUBSTRATES FOR WINDOW CLING DECALS

They can be printed on 8 mil static cling vinyl, but are most often printed on 4 mil low-tack vinyl. Using low-tack, or removable, vinyl allows you to reposition the decal if necessary; and then remove it completely with no residue left behind. When we print decals on low-tack vinyl, we also include a crack-and-peel slit liner on the back for ease in application.

MIRRORED PRINTING FOR MOUNTING INSIDE WINDOWS

Double-sided clings can be printed either face-up for mounting to the outside of windows and doors, or face-down (mirrored) for adhering to the glass on the inside of the store. Mirrored printing is the most common choice, because store owners and managers prefer inside mounting. It prevents vandalism, keeps the decals cleaner for the duration of the promotion or campaign, and the decal can still be viewed clearly from outside of the store.

- Large Run Rhoto-Realistic Graphics: UV Offset Printing

- Short run photo-Realistic Graphics: Digital Printing

- Spot-Color Graphics: Screen Printing

- Inside Mounted Clings: Face-Down (Backward or Mirrored) Printing

- Outside Mounted Clings: Face-Up Printing

MAKING DOUBLE-SIDED WINDOW CLINGS OPAQUE

Since window clings are printed on both sides, opacity is a big deal. You want to be able to clearly read the decal on one side without seeing ghost images of the message on the other side. To do this, we need something between the layers of vinyl in the form of polypropylene block-out film like we used with these decals for Blackout® ( ... yeah, I got that we used "blockout" for "blackout" ), or by using a barrier film. The material used is determined by the size of the run.

BARRIER FILM

For small runs (50 or less), barrier film can be used. The diagram below shows the seven layers of printing and substrate materials that go into printing with barrier film. It basically consists of a layer of silver foil sandwiched between two additional layers of white polypropylene, creating 100% opacity (these layers are depicted with the ➛ symbol). The cling decal is printed on 4 mil clear low-tack vinyl. The layers that make up the barrier film provide complete opacity. The other side of the cling is printed on the barrier film's polypropylene. Lastly, each window cling comes with a crack-an-peel liner for easy application.

Due to material costs and labor involved in using barrier film for window clings and door clings, it is better suited for shorter runs. If you're ordering more than 50 double-sided cling decals for a particular project, we suggest using the block-out film method instead. We'll be happy to take a look at your artwork and order quantity to steer you in the right direction for your project.

- Starting from the bottom, there's a layer of 90# paper that is used as a release liner. It's that part you peel off of a decal before applying it to the glass.

- The next layer up is the 4 mil clear low-tack vinyl. The "low tack" allows the decal to stick to the window, but be easily removed.

- The next layer is the printing on one side of the window cling.

- On top of that is the barrier film: made up of one layer of white polypropylene, then one layer of silver foil, then another layer of white polypropylene.

- Finally, the top layer represents the printing on the other side of the window cling decal.

BLOCK OUT FILM

An alternative to barrier film is 8 mil polypropylene block-out film. The thickness of the white poly material provides approximately 95% opacity. Block-out film is a more economical choice for runs from 50 to 5,000 as it involves less substrate materials and labor.

The diagram below shows the five layers of printing and materials that go into making double-sided window clings opaque with block-out film. This includes two layers of printing (for the front and back sides of the cling decal), the polypropylene substrate, adhesive and liner. The adhesive is permanent on one side; the side that "sticks" to the window is low-tack, meaning it can easily be removed when the promotion has ended. The polypropylene liner is a crack-and-peel slit liner which makes the decal easy to apply.

- Working from the bottom again, the first layer is the slit crack-and-peel poly liner.

- The next layer up is a permanent | removable double-sided adhesive. (The low-tack removable side is the part that will stick to the window when the poly liner is removed; the permanent side of the adhesive sticks to the next layer).

- The layer above the adhesive is the printing on one side of the window cling.

- The next layer is the 8 mil polypropylene.

- And the final layer is the printing on the other side of the decal.

So, to recap:

- Small Runs | Maximum Opacity: Barrier Film

- Larger Runs | High Opacity | Economical: Polypropylene Block-Out Film

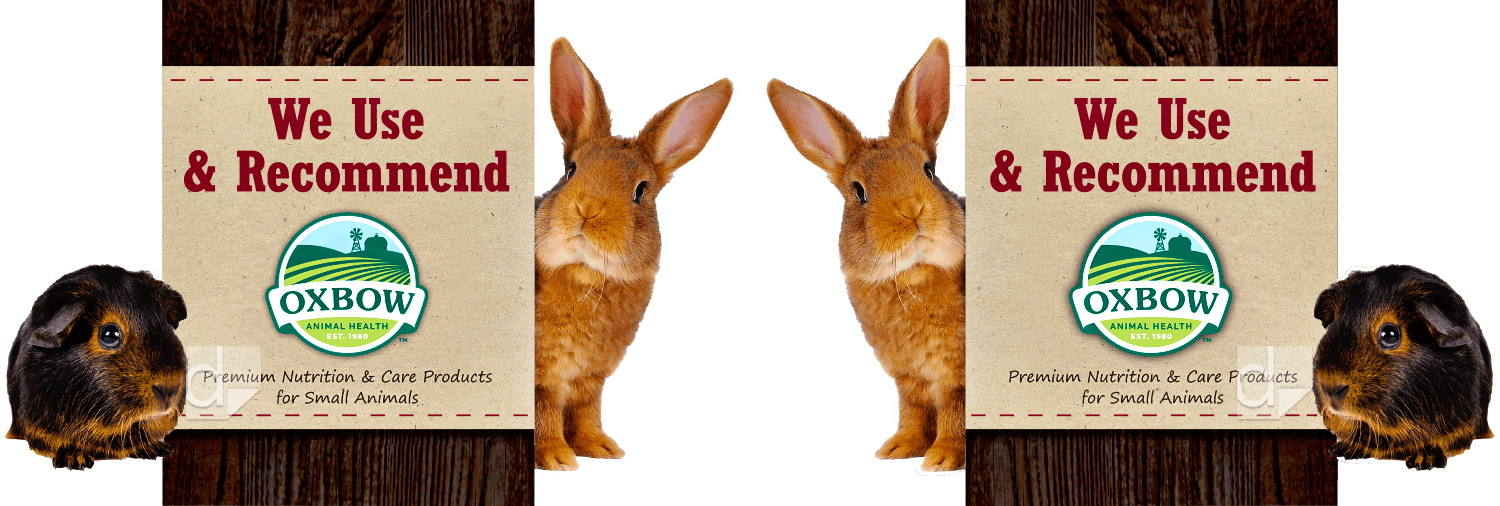

WINDOW CLING DECALS USING BARRIER FILM

The window clings for Oxbow® Animal Health were 4/4-color process digitally printed on 4 mil low-tack vinyl with white barrier film. They were custom die cut to approximately 5.8" x 4".

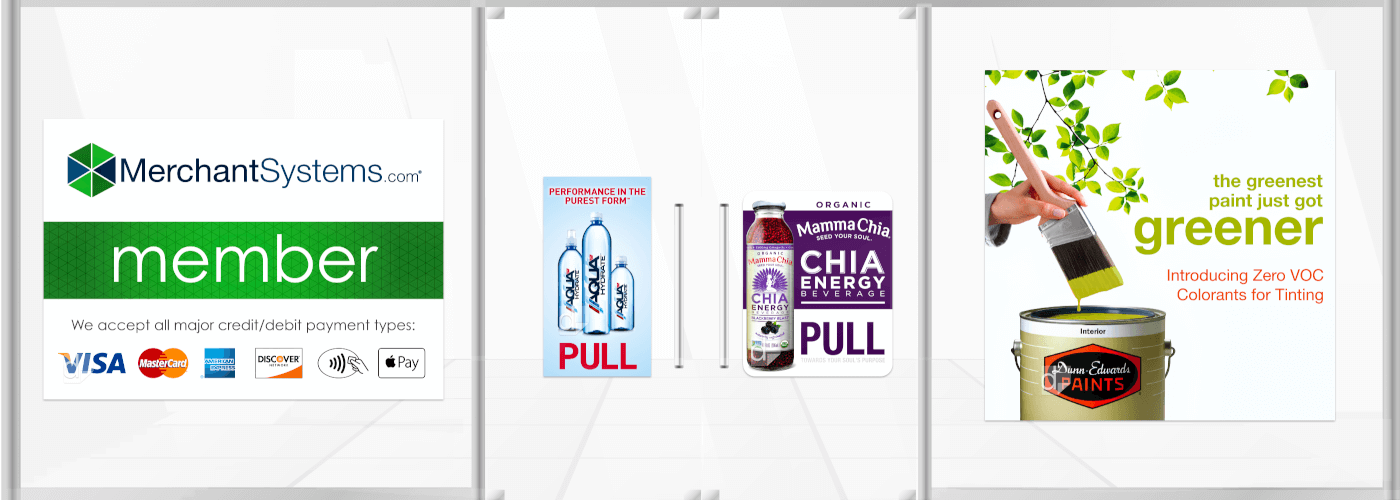

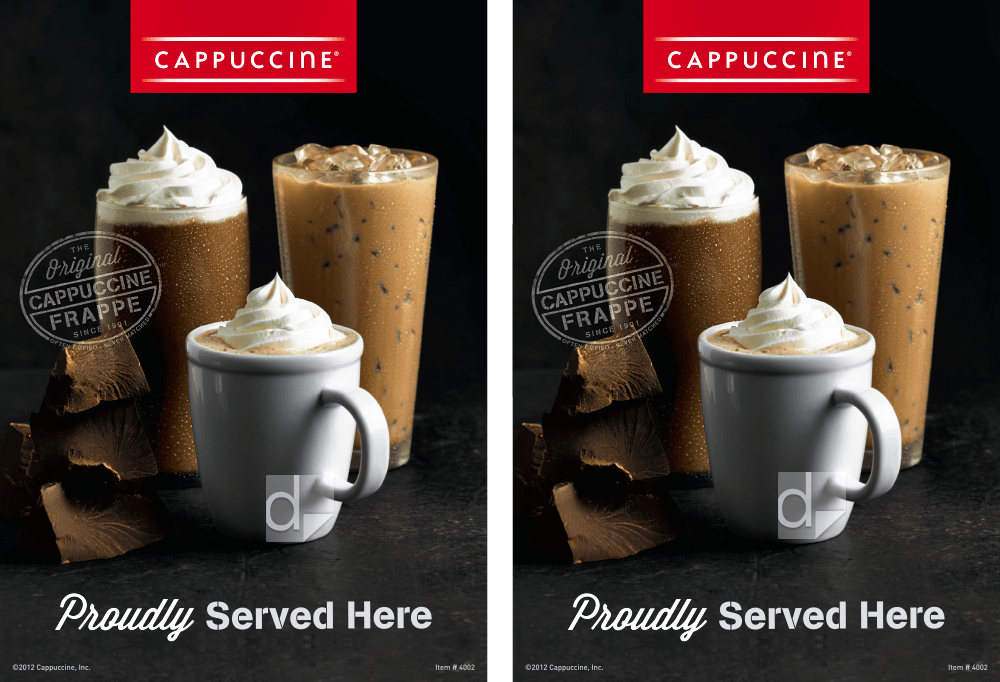

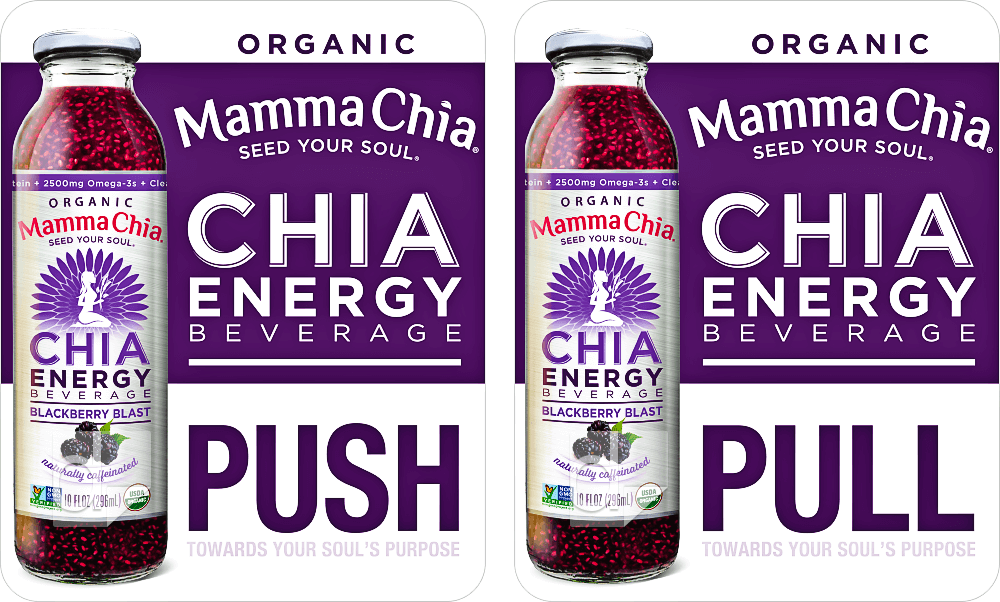

DOUBLE-SIDED DOOR CLINGS

Double-sided door cling decals are made the same way as window clings; the only difference is that they adhere to retail glass entry doors rather than windows. That said, they can be even more powerful than window clings. For starters, consumers get right up to the decal when they come in the store. And, by adding useful information such as "push" and "pull" or business hours, double-sided door clings garner more attention. Because the consumer is likely to read the practical information, they also read the advertisement attached to it. This makes them a great marketing tool since they’re sure to be read as consumers enter and exit the store.

The samples you'll see by clicking that handy little button up there on the right are all double-sided window clings and door clings. For single-sided window clings and perforated window films, please visit our Static Clings & Low-Tack Vinyl Decals page.

WHERE TO USE WINDOW CLINGS

This is just a small list of where and why to use double-sided window clings.

- Advertising a New Product

- Sale Merchandise

- Special Product Promotions

- Upcoming In-Store Events

- Authorized Dealership

- Push | Pull Door Advertising

- Store Hours

- Parking Decals

HOW TO ORDER DOUBLE-SIDED WINDOW & DOOR CLING DECALS

Don't worry about choosing the printing method or substrate. Just let us know where you want them to go and how many you need. We'll take it from there. We'll even help you with your artwork.

Need prices? Head over to our Double-Sided Window Cling Wholesale Price List. We have prices for both short-term and long-life, as well as templates and instructions for a variety of sizes.

If you'd like more information on Window Clings or Door Clings, give us a call at (714) 998-5266 or fill out our free quote form.